As businesses all over the world face an ever-increasing labor shortage,

robotics and automation have become a popular solution. And out of the four

million robots installed globally, over a quarter of them are FANUC. The

ongoing challenge for most companies is finding operators who have the

skills to work with robotics and automation.

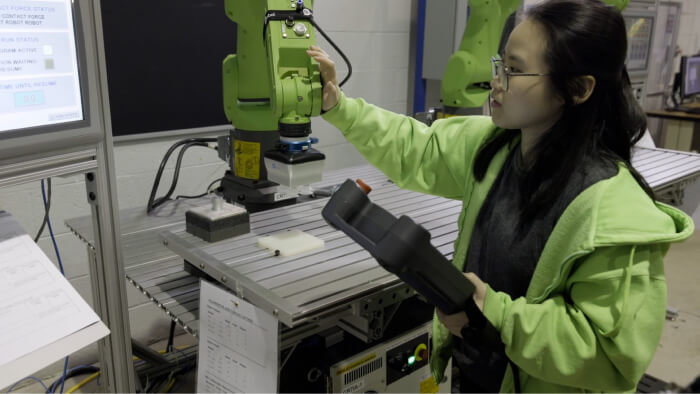

For over a decade, FANUC’s education philosophy has centered on

empowering

the workforce to reach their goals by earning industry-recognized

certifications as well as two and four-year degrees in robotics and

automation.

What that means for today’s businesses is having access to a pipeline

of

highly skilled automation workers ready to help them achieve their goals and

overcome the labor shortage.

The State of Automation Training: Robot Operation to System Integration

FANUC’s early education programs focused on teaching basic robot or CNC

operation. However, automation is quickly evolving because today’s

robotic

production cells include vision systems, sensors, AI, HMIs, and a wide range

of interconnected devices. Because of this, operators need a broader skill

set beyond simply knowing how to operate a robot - they need to understand

the entire automation system.

In addition to robot programming, students who learn to integrate sensors,

and optimize production lines are going to thrive in dynamic production

environments. Their ability to handle complex systems, troubleshoot issues,

and ensure seamless operations contributes significantly to effective

manufacturing processes.

FANUC America offers comprehensive training programs for all aspects of

automation. Whether you’re a student, operator, programmer,

maintenance

specialist, or designer, FANUC’s tailored courses are designed to

maximize

your robotics and CNC skill set.

A Collaborative Approach

FANUC America collaborates with educational institutions and businesses with

a dual purpose: to equip students with the skills needed to obtain stable,

well-paying automation careers, and provide companies a talent pool

consisting of graduates who are experts in advanced robotics and automation.

To date, FANUC has collaborated with over 1,500 high schools, tech training

centers, community colleges and universities to offer hands-on training for

FANUC automation products. Given that FANUC is the most commonly used brand

of robots and automation, the training programs fully support industry

needs.

This tight collaboration between FANUC, education and industry ensures that

the next generation of automation professionals will thrive and grow in a

rapidly changing industry. Companies that hire employees with robotic and

automation skills will achieve higher levels of operational efficiency and

improve their outlook for long-term success in a technology-driven world.

Here’s just some of the advantages that companies can achieve with an

automation-savvy workforce:

Increased Productivity and Efficiency:

- Skilled employees can design, program, and maintain automated

systems,

leading to streamlined processes and higher productivity.

- Automation allows skilled workers to focus on more strategic tasks

versus performing the dull, dirty, and dangerous tasks formerly

associated with manufacturing.

Cost Savings:

- Efficient automation reduces operational costs by minimizing errors,

waste, and downtime.

- Better resource utilization.

Improved Quality and Consistency:

- Skilled workers ensure that automated systems operate consistently.

- Quality control becomes more precise, leading to better products and

services.

Safety Enhancement:

- Automation reduces the need for people to perform potentially hazardous

tasks.

- Employees with automation skills contribute to safer work

environments.

Innovation and Adaptability:

- Skilled workers drive innovation by integrating new technologies and

optimizing existing systems.

- Employees can adapt swiftly to changing market demands.

Competitive Advantage:

- Companies that invest in automation skills training for their employees

have a competitive edge.

- Having skilled employees allows you to deliver products faster, stay

ahead of industry trends, and increase your ability to scale according

to market demands.

Job Creation and Upskilling:

- Automation creates new roles – contrary to the false belief that

robots

eliminate jobs.

- Companies benefit from a workforce capable of handling advanced

technologies.

Optimizing Existing Systems:

- Skilled workers understand the intricacies of existing systems, and can

identify inefficiencies, bottlenecks, and areas for improvement.

Problem Solving and Innovation:

- When faced with challenges, skilled workers think creatively - they

propose innovative solutions, whether it’s automating repetitive

tasks

or enhancing data analytics.

Enhancing Collaboration and Communication:

- Skilled workers bridge gaps between departments, ensuring smooth

communication and alignment.

Join the Automation Generation

Skilled workers play a crucial role in driving innovation through technology

integration. FANUC America’s commitment to workforce development

transcends

traditional training. It’s about nurturing minds, fostering

innovation, and

driving the future of manufacturing.

Whether you’re a manager searching for employees with advanced automation

skills, a student considering your future, or you’re employed but looking

for a different pathway – now is the time to join the automation generation.

Learn How FANUC Can

Help