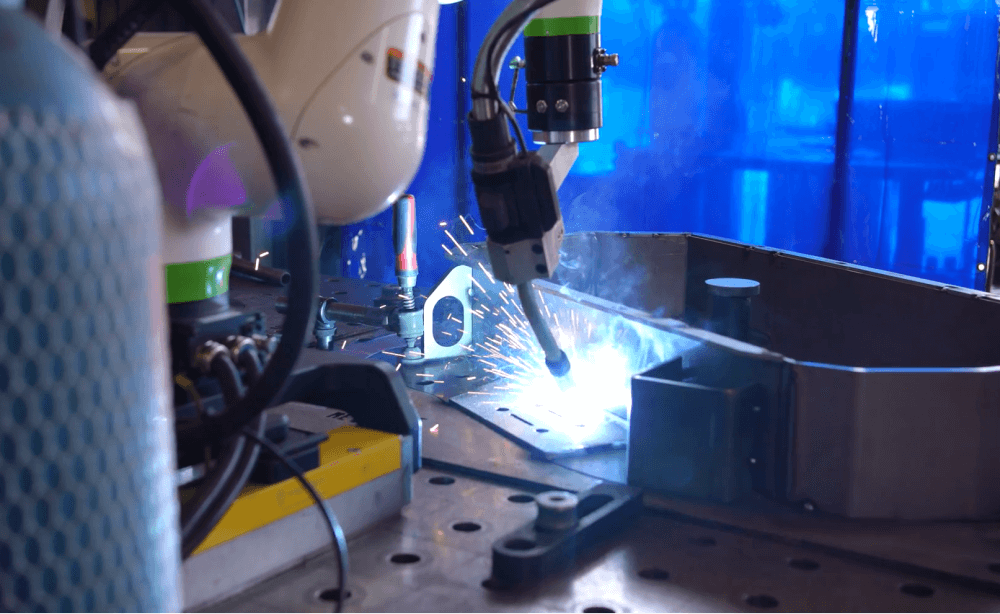

Welding cobots, a term derived from ‘collaborative robots,’ are

an

innovative solution for robotic welding. Unlike thesetraditional welding

robots, cobots are designed to work alongside humans in a shared workspace.

They are engineered with sophisticated sensors and control systems, allowing

safe, efficient interaction with human operators. In today’s world

skilled

welders are hard to find, so an increasing number of companies use welding

cobots to automate the welding processes including high-mix, low-volume part

runs. This strategy then frees up skilled welders to tackle more complex

welding projects. And, as production levels grow, companies that have tried

cobot welders often look to traditional high-speed robotic welders to take

on low-mix, high-volume production.

Evolution of Robotic Welding

Robotic welding originated in the 1980s, marking a significant leap in

manufacturing technology. Due to their high-speed operations and lack of

sensing capabilities, traditional robotic systems are caged off from human

workers to prevent accidents. Over the decades, advancements in sensor

technology and artificial intelligence have paved the way for the emergence

of welding cobots. These modern marvels encapsulate the essence of

human-robot collaboration and make a great choice for small- to medium-sized

companies that are new to automation.

Differences Between Traditional Robots and Cobots

Traditional welding robots and cobots differ fundamentally in their

operation and interaction with human workers. Traditional robots operate

autonomously within caged areas, requiring a clear separation from human

activities to ensure safety. On the other hand, cobots are designed to share

the workspace with humans, with safety features that allow for close

interaction. The intuitive control systems of cobots enable easy programming

and operation, making them extremely easy to program and use. In addition,

cobots are compact and provide the flexibility and scalability to handle new

tasks in a matter of minutes.

The Welder Shortage Crisis

Understanding the Crisis

The manufacturing sector is experiencing a significant shortage of skilled

welders. A combination of factors contributes to this crisis. Firstly, a

generation of skilled welders is approaching retirement, and there aren't

enough trained individuals to fill the gap. Secondly, despite its critical

role in manufacturing, welding often gets overlooked as a viable career by

the younger generation. The perception of welding as a dirty, dangerous, and

demanding job has deterred many from pursuing a career in this field.

Lastly, the rapid advancements in manufacturing technology require higher

skill and training, further widening the gap between available jobs and

qualified welders.

The Role of Cobot Welding in Addressing the Shortage

Cobot welding emerges as a promising solution to mitigate the welder

shortage crisis. Cobots allow human welders to focus on more complex and

critical aspects of the welding process by taking on repetitive, strenuous,

and precision-demanding tasks. Cobots come with user-friendly interfaces,

allowing for quick learning and easy operation, thus reducing the barrier to

entry for new welders. Moreover, the collaborative nature of cobots creates

a more engaging and safer work environment, potentially attracting a younger

workforce to the welding profession.

Cobot welding also allows for a scalable solution to varying production

demands. Companies can deploy cobots to maintain a steady production pace,

even in the face of fluctuating workforce availability. The integration of

cobots can help businesses keep up with technological advancements in the

welding industry, ensuring they remain competitive.

The deployment of welding cobots not only addresses the immediate issue of

welder shortage but also sets a foundation for a more sustainable and

technologically advanced welding industry. By augmenting human capabilities

with cobots, companies are better positioned to solve current and future

challenges in welding operations.

Benefits of Using Welding Cobots

Enhanced Precision and Consistency

Welding cobots, with their sophisticated control systems and steady robotic

arms, significantly enhance the precision and consistency of welding

operations. The meticulous control over welding parameters such as speed,

angle, and distance ensures that every weld is performed to the exact

specifications, reducing the margin of error that may be encountered in

manual welding. This level of precision is crucial, especially in industries

like aerospace or automotive manufacturing, where the quality of welds is

paramount.

Unlike human operators, cobots are immune to fatigue, ensuring consistent

weld quality 24 hours a day. This consistency translates to fewer defects,

lower rework costs, and higher product quality. The precision and

consistency provided by welding cobots is hard to match, making them an

indispensable asset in modern welding operaitons.

Increased Safety in Work Environments

Safety is paramount in welding or any manufacturing operations. Welding

cobots are designed with several built-in safety features that significantly

mitigate workplace risks. These features include force-limited joints,

real-time monitoring systems, and immediate cessation of operations if a

human enters a predefined proximity. Such safety measures minimize the

chances of accidents and collisions, ensuring a safer work environment.

By handling hazardous tasks such as operating in high-heat zones or dealing

with toxic materials, cobots drastically reduce the exposure of human

workers to potential health hazards associated with welding. A safer

workplace not only protects workers, it may encourage more

people to become welders. Integrating cobots into welding operations

symbolizes a significant step towards creating a safer, more controlled work

environment, showcasing the profound impact of collaborative robotics in

industrial safety protocols.

Improved Efficiency and Productivity

Welding cobots plays a big role in boosting welding efficiency and

productivity. With their tireless work ethic, cobots enable round-the-clock

operations, which are crucial in meeting tight production schedules and

deadlines. Their swift setup and ease of reconfiguration facilitate a faster

transition between different welding tasks, significantly reducing downtime

often associated with manual retooling.

The ability of cobots to handle repetitive and mundane tasks with a high

degree of speed and accuracy leads to increased throughput and better

resource utilization. The seamless execution of welding cobots results in

higher productivity rates, lower operating costs and optimized workflows,

enabling companies to maximize efficiencies and profits.

Flexibility and Ease of Deployment

One of the defining traits of welding cobots is their flexibility and ease

of deployment. Unlike traditional robots, cobots do not require extensive

setup or specialized facilities. Their compact design, user-friendly

interface, and easy programming make them highly adaptable to various

welding tasks and operational environments. This swift deployment and

redeployment across different tasks or locations are particularly beneficial

for small to medium-sized enterprises that may not have the resources for a

large-scale robotic system, but looking to automate one or more welding

processes.

The versatility of cobots allows companies to quickly adjust to new project

requirements. This flexibility fosters a more agile manufacturing

environment to meet the diverse and evolving demands of today’s

industrial

landscape. Through their easy integration and adaptable nature, welding

cobots help bridge the gap between automation and human-centric operations.

Technical Aspects of Welding Cobots

Key Components and Their Functions

Robotic Arm

The robotic arm is essentially the backbone of the welding cobot. It is

meticulously engineered to provide the movement, reach, and flexibility

required to perform welding tasks across various workpieces. The precision

in movement ensures that the welding torch is accurately positioned,

significantly impacting weld quality. Moreover, the robotic arm's speed and

accuracy play a pivotal role in enhancing welding efficiency and

productivity.

Welding Power Source

The welding power source is the heart of the welding operation. It supplies

the required energy to create stable, high-quality welds. The compatibility

between the power source and the welding cobot is crucial as it directly

influences the performance and the outcome of the welding tasks. It's

essential to match the power source to the welding cobot and the task at

hand to ensure optimal performance, making the selection of an appropriate

power source a critical consideration.

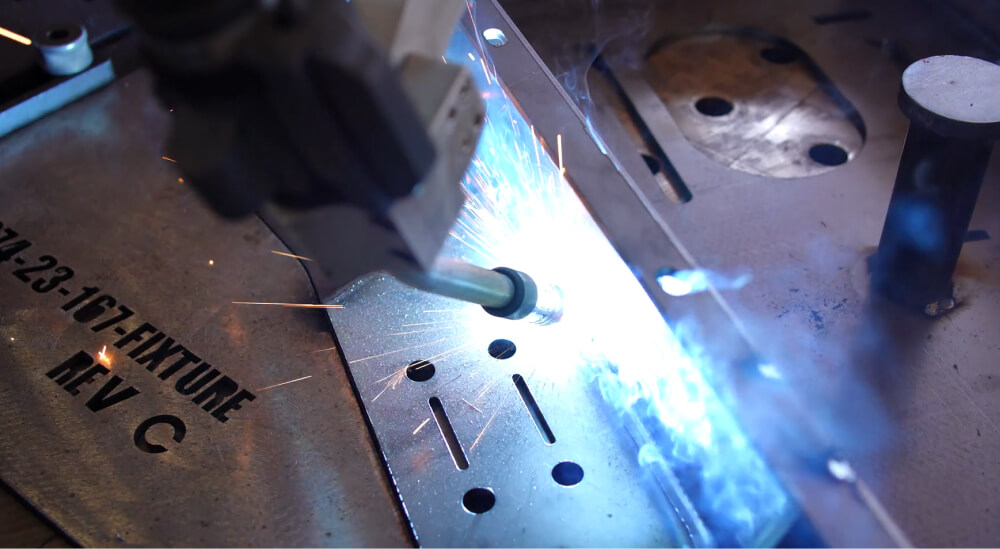

Torch

The welding torch directs the welding arc to the precise location on the

workpiece to ensure accurate, high-quality welds. The design and maintenance

of the torch are crucial as it interacts directly with the workpiece, and

any misalignment or malfunction could result in subpar welds.

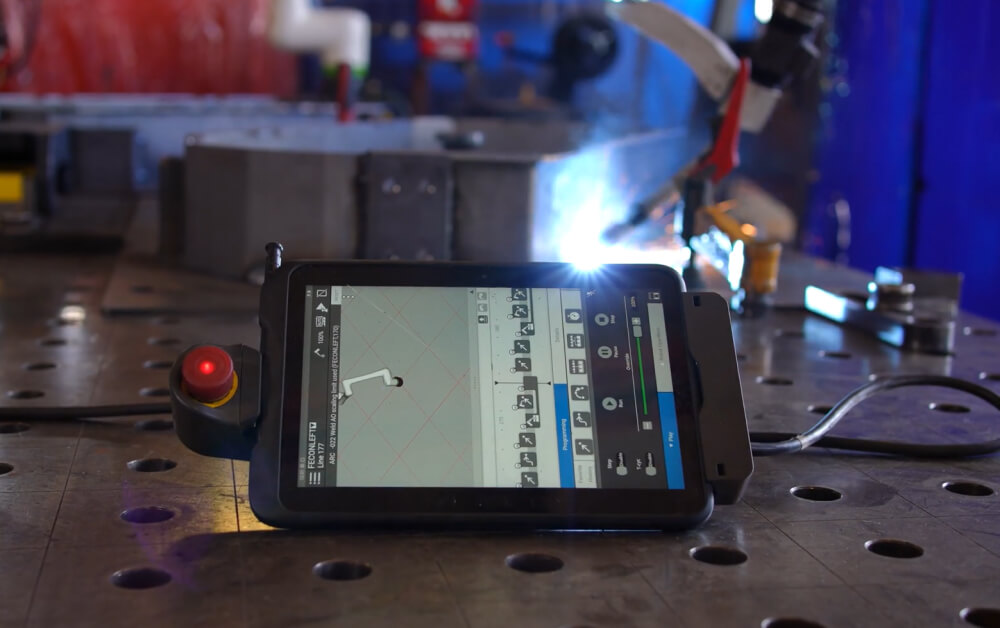

Teaching Device

A teaching device, which could be a pendant or tablet, allows users to

program a cobot to perform welding tasks. An intuitive interface makes it

quick and easy to setup the welding path and parameters.

Welding Software

Welding software is the cornerstone of intelligent cobot welding. It adjusts

the welding program to maintain weld quality, especially when dealing with

inconsistent production parts. Advanced software options like Touch Sensing,

Arc Seam Tracking, and laser vision enhance the cobot's adaptability by

adding seam finding, seam tracking, or joint measurement capabilities. These

features are instrumental in ensuring that the cobot can effectively handle

various welding tasks with different workpiece geometries and conditions.

Pre-built Welding Libraries

Most manufacturers equip their cobots with pre-built welding libraries that

simplify the application of cobots to welding tasks. Functions like tool-tip

alignment and wire feed rate optimization are part of these libraries. They

enable easy adaptation to specific welding requirements, making the

transition to cobot welding much smoother for both small and large

companies.

Cable Feed Equipment

Although cobots generally have a lower payload capacity than traditional

robots, the design accommodates the cable feed equipment to be located off

the robot. This arrangement facilitates the setup and operation of the cobot

welding system, ensuring that its lower payload capacity does not impede its

functionality in the welding process.

Welding Techniques and Applications

Welding cobots support various welding techniques, including Arc welding,

MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), laser, plasma, ultrasonic,

and spot welding. Cobots can also be configured for soldering or brazing if

needed. This adaptability is notable in industries requiring different

welding techniques for varied materials and products.

With cobots, fabricators can create specific weld programs for individual

workpieces or parts, quickly switch between different weld programs and

workpieces, and establish a consistent, repeatable, semi-autonomous weld

workflow for increased productivity. This level of automation enables taking

on more orders without the need for additional welders, thus improving the

pricing, quoting process, and overall throughput.

The ability to automate almost any type of weld, including the commonly

automated MIG welds in thicker metal applications like aluminum, stainless

steel, and carbon steel, underscores the cobots’ extensive application

in

welding tasks. Cobots can also be integrated with Gas Metal Arc Welding

(GMAW) and Gas Tungsten Arc Welding (GTAW) processes, although using cobots

for different passes in these processes is less common. With their ease of

programming and adaptability, welding cobots are revolutionizing welding

applications across diverse sectors.

Programming and Automation

Programming welding cobots is streamlined to accommodate both seasoned

programmers and those with limited programming experience. A notable feature

of cobot welding systems is the reduced programming time facilitated by

user-friendly software solutions.

For instance, FANUC’s ARC Tool Software comes with an easy-to-program

interface that not only supports simple applications but also provides the

ability to utilize advanced features such as Weaving and iRVision, thereby

reducing the programming time and improving the bottom line for businesses.

The ease of programming extends to developing specific weld programs for

individual workpieces or parts and the ability to quickly switch between

different weld programs and workpieces as required swiftly. This level of

automation establishes a consistent, repeatable, and semi-autonomous weld

workflow, significantly enhancing productivity. It also allows for the

storage of weld programs for future reference, ensuring a quicker setup for

recurring welding tasks and thereby increasing the throughput of each shift.

Automation with cobots allows for a continual welding process as workers can

safely load and unload parts while the cobot welds, ensuring the system runs

continually for maximum productivity. This blend of automation and human

interaction paves the way for a more efficient welding workflow, opening new

avenues for scaling production and improving operational efficiencies.

Integration with Other Systems

Welding cobots are designed with integration in mind, allowing them to work

seamlessly alongside existing systems and processes in a manufacturing

setup. Industrial end users have been the driving force behind the

integration of welding systems and cobots. Companies like FANUC provide

welding cobots that work closely with your welding processes, showcasing the

industry's advanced cobot technology.

Integrating a welding cobot into an existing welding cell or other

manufacturing systems involves reconfiguring the application space. This

could mean utilizing a closed shop or opening it up to allow welders to move

around. System integration firms help manufacturing companies

design and commission industrial robots and other advanced automation

systems, with some able to install cobots for welding applications in a

matter of hours or days instead of weeks or months.

Integration specialists can help outfit the ideal setup, ensuring the

welding cobot and the existing systems work together. This integration is

not just about the physical setup; it's about ensuring the workflow, the

data exchange, and the human-machine interactions are optimized for the best

performance.

Comparative Analysis: Cobot Welding vs. Other Methods

Distinct Features of Different Welding Approaches

Welding methodologies vary significantly in their features and applications.

The primary categorization can be seen between manual welding, traditional

automated welding, and collaborative welding (cobot welding).

Manual Welding

In manual welding, a human welder performs the operations. The quality of

products relies heavily on their skills, ideal for small-scale operations or

detailed work requiring human touch and expertise. However, it could be

prone to common quality problems such as weld spatter, porosity, and shallow

penetration.

Traditional Automated Welding

Traditional automation in welding involves fully or semi-automated robotic

systems. In fully-automated robotic welding, robots guide the metal

throughout the process, while in semi-automated welding, a person loads and

unloads the metal. This method was initially ideal for large-scale

operations but has found a place in small and medium businesses due to its

benefits in productivity and quality.

Collaborative Welding (Cobot Welding)

Cobots, on the other hand, blend the best of both worlds. They work

alongside humans, enabling easy programming, quick adjustments, and

transitions between welding tasks. Cobots

are known for their flexibility, ease of programming, and lower

overall investment, making them a quick solution to address welder

shortages, and suitable for low-volume work.

Each welding method has its own advantages and disadvantages that must be

weighed against the specific needs and constraints of the welding task at

hand.

Traditional Automation vs. Collaborative Welding vs. Manual Welding

The welding industry has evolved over the years with the advent of

automation and collaborative robots (cobots). Each welding approach -

traditional automation, collaborative welding, and manual welding, has its

place in the industry based on certain factors, including the scale of

operations, the level of precision required, and the available resources.

Traditional Automation

Involves the use of robotic systems that are programmed to carry out welding

tasks autonomously. They are ideal for large-scale production where

high-speed and high-volume welding is required. The initial setup cost is

high, requiring a significant amount of space and specialized setup. They

offer high precision, consistency, and efficiency, reducing the likelihood

of errors and rework.

Collaborative Welding

Cobots are designed to work alongside human operators. They are easier to

program, set up, and they require less space compared to traditional robots.

Cobots are a more economical solution for small to medium-sized enterprises

or for operations where flexibility and easy reconfiguration are essential.

They offer a balance between automation and human intervention, allowing for

quick adjustments and transitions between different welding tasks. They can

be easily moved around and redeployed to different tasks or locations.

Manual Welding

Relies entirely on the skill and expertise of human welders. It is ideal for

specialized welding tasks, repair work, or small-scale operations. Manual

welding allows for a high level of customization and adaptability to

different tasks, but it is slower and may lack the consistency and precision

of automated systems.

The choice between these welding approaches depends largely on the specific

needs and constraints of the operation. While traditional automation may be

suitable for high-volume production, collaborative welding offers a flexible

and cost-effective solution for various applications. Manual welding, on the

other hand, remains indispensable for tasks requiring a high level of

craftsmanship and customization.

Each welding method: manual welding, traditional automated welding, and

collaborative welding, has its own set of advantages and disadvantages.

These pros and cons can significantly influence the choice of welding method

for a particular application or industry.

Pros and Cons of Each Method

Manual Welding

- Pros: High level of customization, adaptability to different tasks,

ideal for repair work or specialized welding tasks.

- Cons: Slower speed, inconsistency in weld quality, higher likelihood of

errors, and may require a higher level of skill and training.

Traditional Automated Welding

- Pros: High precision, consistency, and efficiency. Ideal for

high-volume production, reduces the likelihood of errors and rework and

can operate round the clock.

- Cons: High initial setup cost, requires significant space and

specialized setup, less flexible in adapting to different tasks or

changes in production.

Collaborative Welding (Cobot Welding)

- Pros: Ease of programming and setup, requires less space, more

economical for small to medium-sized enterprises. Offers a balance

between automation and human intervention, allowing for quick

adjustments and transitions between different welding tasks.

- Cons: May not be suitable for high-volume production compared to

traditional automated welding, may require a more controlled environment

to ensure safety, and may not offer the same level of precision as

traditional automated welding in complex tasks.

Understanding the pros and cons of each welding method can help

businesses

and industries make informed decisions based on their specific needs, budget

constraints, and the level of precision and consistency required in their

welding operations.

Challenges and Limitations

Skill and Training Requirements

Implementing welding cobots in a manufacturing setup necessitates a certain

level of skill and training for operators. Understanding the operating

procedures of welding cobots is crucial for ensuring efficiency and safety.

Welding cobots are designed with simplicity in mind, suitable for welders

new to robotic welding automation. A detailed step-by-step process is often

provided to guide operators on handling the cobot efficiently.

With the growing use of welding robots, the role of robotic welder welding

operators has become increasingly significant. They are responsible for

programming and operating welding robots to perform various tasks, including

MIG, TIG, and stick welding.

Operating a cobot requires some training but not extensive welding or

programming experience. This starkly contrasts traditional robotic welding

cells that demand more extensive welding or programming experience. Cobots

present a lower barrier to entry, making them an attractive option for

operations that struggle with skill shortages. Most suppliers offer training

to get staff comfortable with new equipment, ensuring a smooth transition to

utilizing cobots for welding tasks.

Limitations in Complex Tasks

While welding cobots bring many benefits to the table, they have limitations

when handling complex welding tasks. Their application can be constrained in

scenarios requiring intricate welding or tasks requiring high precision and

control. The accuracy of cobots might fall short in comparison to

traditional automated welding systems, especially in highly specialized or

complex welding applications.

Cobots may struggle with welding tasks that involve complicated geometries

or require multi-layer welding. They are designed for simpler, more

straightforward welding operations and may lack the advanced control systems

of traditional welding robots. Traditional automated welding systems might

still be preferred for complex or highly specialized welding tasks.

There's a limitation in the payload and the reach of cobots, which can be a

hurdle when dealing with large workpieces or extensive welding tasks. This

may necessitate using traditional robots for such demanding scenarios,

ensuring that the welding tasks are executed accurately and efficiently.

Maintenance and Durability Concerns

Much like traditional robots, welding cobots require regular maintenance to

ensure they function optimally over time. The maintenance routine usually

encompasses checking the robotic arm, the welding torch, and other integral

components for wear and tear. Overlooking maintenance can lead to decreased

performance, accuracy, and, potentially, the premature failure of the cobot.

Durability is another concern. The harsh conditions prevalent in welding

environments, such as high temperatures and the presence of metal spatter,

can take a toll on the lifespan of the cobot. This may necessitate frequent

replacements of certain parts or additional protective measures to safeguard

the cobot against the harsh welding environment.

Any malfunction or breakdown in the cobot system can lead to production

downtime, affecting the overall productivity and efficiency of the

manufacturing process. Therefore, having a robust maintenance schedule and

ensuring that the cobots are well-protected against harsh welding conditions

are crucial for realizing the long-term benefits of cobot welding.

Human-Cobot Interaction in the Welding Industry

Role of Human Welders with Cobots

The advent of collaborative robots in the welding industry doesn’t

signify

the replacement of human welders. It denotes a shift in their roles within

the manufacturing environment. Cobots are designed to work alongside humans,

assisting in repetitive, strenuous, or hazardous tasks, allowing human

welders to focus on more complex, critical, or creative aspects of welding

tasks.

Human welders play a vital role in overseeing the operations carried out by

cobots, ensuring the quality of welds, and making necessary adjustments to

the cobot settings to achieve desired welding outcomes. They are

instrumental in programming the cobots, setting them up for different

welding tasks, and ensuring they operate safely and effectively.

Human welders can leverage the capabilities of cobots to increase their

productivity and efficiency. Cobots can handle the more monotonous or

dangerous aspects of welding, reducing the risk of occupational hazards for

human welders and freeing them up to tackle more challenging welding tasks

or focus on other important areas of the manufacturing process.

In essence, the collaboration between human welders and cobots facilitates a

synergistic relationship where both parties benefit. Human welders can

enhance their skill set by learning to operate and program cobots, while

cobots can augment the welding process by taking on more repetitive or

hazardous tasks. This collaboration aims to foster a safer, more productive,

and more satisfying work environment in the welding industry.

Training and Transitioning to Cobot Systems

Transitioning to cobot systems from manual or traditional automated welding

systems necessitates a certain level of training for the existing workforce.

Training programs are crucial for ensuring that operators and welders are

comfortable with the new technology and can utilize it to its full

potential. These programs typically cover the basics of operating the cobot,

programming it for various welding tasks, and troubleshooting common issues.

A significant advantage of cobots is their user-friendly interface and ease

of programming, which often allows for a smoother transition. This ease of

use reduces the learning curve significantly, enabling welders and operators

to quickly adapt to the new technology. Moreover, many cobot manufacturers

offer comprehensive training programs, both online and on-site, to help

facilitate this transition.

The transition also involves adapting the existing workflow and processes to

accommodate the new cobot systems. This may include reconfiguring the

workspace, setting up the cobots for the specific welding tasks, and

integrating them with other existing systems and machinery.

The transition to cobot systems can also open up opportunities for

upskilling the workforce. As welders and operators learn to work with and

program the cobots, they can acquire new skills that are valuable in the

modern manufacturing environment. Overall, with the right training and

support, transitioning to cobot systems can be a smooth process that

enhances the capabilities and skills of the existing workforce while

improving the efficiency and productivity of the welding operations.

Case Studies: Real-world Applications

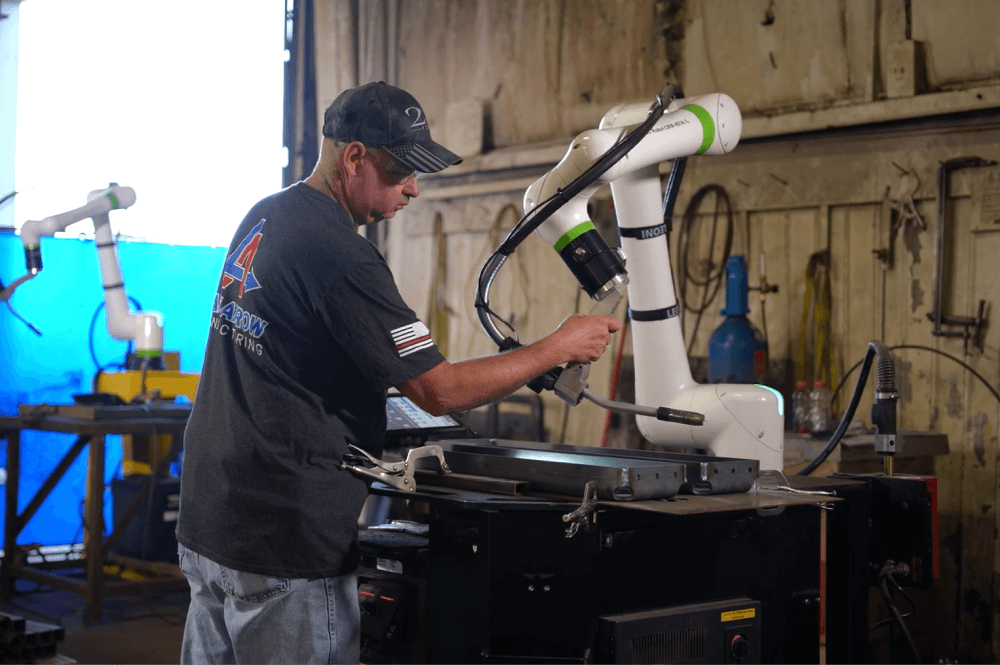

Small-scale Manufacturing: Last Arrow Manufacturing

Small-scale manufacturers often grapple with the challenge of maintaining

cost-effectiveness while ensuring quality and flexibility in their

operations. Last Arrow Manufacturing, an Ohio-based contract manufacturer,

exemplified a successful transition towards automated welding while

retaining flexibility in their production processes.

The challenge was to automate simple, repetitive welding tasks without

compromising on quality, and at the same time, free up skilled welders for

more complex projects. The solution came in the form of FANUC's CRX welding

cobot, which provided the much-needed flexibility and ease of use.

Upon integrating FANUC’s welding cobots, Last Arrow Manufacturing

witnessed

a quick uptick in business, attributing to increased productivity, higher

profits, and improved employee satisfaction. The ease of programming was

highlighted by their Lead Programmer, Scott Musser, who with over 20 years

of experience in robotic programming, found the user-interface extremely

user-friendly.

Matt Bowling, the President of Last Arrow Manufacturing, expressed that the

integration of welding cobots provided a solution that works for their

business model, which requires consistent changeover due to the nature of

their projects. The case of Last Arrow Manufacturing illustrates the

potential of cobot integration in enhancing profitability, employee

satisfaction, and operational flexibility in small-scale manufacturing

setups, especially when dealing with frequent process changeovers and a

variety of welding tasks.

Investment Insights

In the manufacturing sector, the integration of cobots, particularly for

welding tasks, is viewed as a forward-thinking investment. This section

explores the reasoning behind investing in cobot welders, dives into a

comparative financial analysis between cobot and manual welding, and

discusses the return on investment along with the payback period

associated with such an investment.

Reasons to Invest in Cobot Welders

Investing in cobot welders comes with a plethora of benefits that

significantly contribute to a manufacturing facility’s bottom line.

- Ease of Use: Cobots are designed to be user-friendly, making it

possible for welders with beginner-level skills to operate them

efficiently. Their easy maneuverability and the straightforward process

of position or multipass welding make them a suitable choice for various

welding tasks.

- Cost-Effectiveness: The initial investment in a welding cobot can

range from $50,000 to $100,000 or more. Although

this might seem steep, the long-term cost savings are substantial. The

automation of welding tasks leads to increased productivity, improved

quality, and reduced labor costs, presenting a cost-effective solution

in the long run.

- Market Growth: The cobot market is on a trajectory of rapid growth,

with an anticipated growth of 50% in 2023. This growth is propelled by

the looming welder shortage estimated at about 400,000 by 2024.

Investing in cobot welders not only addresses the labor shortage but

also positions a company to stay competitive in a rapidly evolving

market.

- Support and Accessibility: Post-sales support is crucial for ensuring

the smooth operation of cobot welders. Reputable cobot providers offer

accessible support, often in real-time over video calls, ensuring any

issues are resolved promptly, thus minimizing downtime.

- Addressing Labor Shortage: The severe labor shortage in the welding

sector is pushing manufacturers to seek automated solutions. Cobot

welders stand as a viable solution to this problem, helping maintain

production levels even in the face of dwindling interest in welding

careers among the younger generation.

Comparative Financial Analysis: Cobot vs. Manual Welding

In a financial analysis between cobot and manual welding, several aspects

come into play. The primary focus areas are the initial investment,

operational costs, productivity, and output quality.

The initial investment for setting up a cobot welding station might be higher

than that of a manual welding station due to the cost of the cobot and the

associated setup. However, this initial investment can be quickly offset by

the subsequent reduction in operational costs and increased productivity.

Operational costs in a manual welding setup are primarily driven by labor

costs, which include salaries, benefits, and training. In contrast, the

operational costs in a cobot welding setup are significantly lower

post-setup, with maintenance and energy being the primary ongoing costs.

Reducing labor costs is one of the most substantial financial benefits of

transitioning to cobot welding.

Productivity is another critical area where cobot welding shines. Cobots can

operate continuously without fatigue, leading to a substantial increase in

production output. They also ensure consistent quality, reducing the rate of

defective or sub-standard products, thus minimizing losses associated with

rework or scrap.

The output quality in cobot welding is often higher than manual welding,

especially for repetitive and straightforward tasks. Cobots provide precise

and consistent welding, which is crucial for meeting the stringent quality

standards in industries like automotive and aerospace.

In the long term, the financial benefits of investing in cobot welding

become evident. The reduction in operational costs, combined with increased

productivity and improved quality, contributes to a higher return on

investment, making cobot welding a financially sound choice for

manufacturers looking to modernize their operations and stay competitive in

the market.

Return on Investment and Payback Period

The Return on Investment (ROI) and payback period are crucial metrics for

manufacturers considering the integration of cobot welding into their

operations. These metrics provide a clear financial picture of the long-term

value and the time frame within which the initial investment can be

recovered.

The ROI is calculated by comparing the cost of investment to the monetary

benefits derived from the investment over a specific period. In the case of

cobot welding, the benefits include savings from reduced labor costs,

increased productivity, and improved quality which leads to lesser rework

and waste. The ROI for cobot welding can be significantly high, especially

in low-volume production environments with substantial cost savings and

productivity gains.

The payback period, however, is the time it takes for the savings and

benefits to equal the initial investment. Typically, the payback period for

cobot welding systems can range from a few months to a couple of years,

depending on the scale of operations and the cost of the cobot system. A

shorter payback period is often seen in scenarios where manual welding

operations are replaced in highly repetitive and labor-intensive tasks, thus

quickly realizing the cost-saving benefits of automation.

Technological Advancements on the Horizon

The future of cobot welding is intertwined with the continual advancements

in technology. These advancements aim at making cobot welding more

efficient, user-friendly, and adaptable to various manufacturing scenarios.

One notable trend is the integration of Artificial Intelligence (AI) and

Machine Learning (ML) into cobot systems. This integration enables cobots to

learn from their environment and improve their performance over time. For

instance, they can learn to adjust their welding parameters autonomously to

account for variations in materials or environmental conditions, leading to

enhanced welding consistency and quality.

Advancements in sensor technology and vision systems are poised to

significantly improve the precision and capabilities of cobot welders.

Enhanced sensors and vision systems enable cobots to better understand their

environment, allowing for more accurate welding and improved error

detection.

Developing more sophisticated user interfaces and programming environments

is on the horizon. These advancements will make it easier for operators to

program and monitor cobot welders, reducing the barrier to entry and making

cobot welding accessible to a broader range of manufacturers.

Growth of the Cobot Market

The cobot market is expected to experience robust growth in the

coming years. This growth is driven by the increasing acceptance and

adoption of cobot welding in various manufacturing industry sectors. The

escalating demand for precision, consistency, and efficiency in welding

operations propels the need for cobot welding systems. Furthermore, the

looming labor shortages in the welding sector significantly contribute to

the growing interest in and adoption of cobot welding solutions.

Evolving Workplace Dynamics with Cobots

Integrating cobots in the welding sector is gradually altering the workplace

dynamics. Cobots are taking over repetitive and hazardous tasks, allowing

human welders to focus on more complex and creative aspects of welding

projects. This shift is fostering a more engaging and safer work

environment. Moreover, the ease of use and the low learning curve associated

with cobots encourage a more inclusive workforce, where individuals with

varying levels of technical expertise can contribute to welding projects.

This evolution is expected to continue as cobots become more advanced and

commonplace in the welding industry, promoting a harmonious collaboration

between human workers and robotic systems and ultimately leading to enhanced

productivity and job satisfaction among welding professionals.

Conclusion: The Role of Welding Cobots in Modern Manufacturing

The integration of welding cobots in modern manufacturing unveils a realm of

possibilities. Amidst the backdrop of labor shortages and the incessant

demand for high-quality products, cobot welding emerges as a viable

solution. Its adoption signals a step towards modernized manufacturing

processes characterized by increased efficiency, precision, and safety.

With their user-friendly interfaces, Cobots are demystifying robotics,

making it accessible to a broader spectrum of the workforce. This

inclusivity fosters a conducive environment for skill development and

knowledge transfer between human workers and robotic systems.

Moreover, the financial implications of integrating cobot welding are

profound. The initial investment is quickly offset by the substantial

reduction in operational costs and the notable increase in productivity.

Additionally, the competitive advantage gained through higher quality and

consistency in welding operations is invaluable.

Technological advancements foretell a future where cobots are integral to

manufacturing. They are poised to become more intelligent, adaptable, and

easier to operate, further solidifying their position in the manufacturing

landscape.

In summation, the role of welding cobots is pivotal in addressing modern

manufacturing challenges. They embody a significant stride towards creating

a more efficient, inclusive, and innovative manufacturing ecosystem, gearing

industries towards a future of enhanced productivity and global

competitiveness.

FANUC Welding Cobots

Explore a future of precision with FANUC Welding Cobots! Discover how our

cutting-edge cobot technology can revolutionize your welding operations,

ensuring impeccable quality, efficiency, and safety. Step into the future of

manufacturing with FANUC. Contact us today to learn more about our

innovative cobot welding solutions and how they can be tailored to meet your

production needs.

Key Takeaways

- Addressing Labor Shortages: The growing labor shortage in the welding

sector is a pressing issue, and cobot welding offers a viable solution

by automating routine tasks and maintaining production levels.

- Enhanced Precision and Safety: Cobots bring a new level of precision

to welding tasks, reducing errors and ensuring a safer work environment

by taking over hazardous tasks.

- Cost-Efficiency and ROI: Despite the initial investment, the long-term

cost savings, increased productivity, and potential for high return on

investment make cobot welding a financially sound choice.

- Ease of Integration: The user-friendly interfaces and ease of

programming make cobots an accessible technological upgrade, even for

small-scale manufacturers.

- Market Growth and Future Trends: The cobot market is on a trajectory

of rapid growth, propelled by technological advancements like AI

integration, improved sensor technology, and more sophisticated user

interfaces.

- Industry Applications: Real-world applications in various manufacturing

sectors illustrate the tangible benefits and successes of integrating

cobot welding into production processes.

- Evolving Workplace Dynamics: Cobots are fostering a more engaging,

inclusive, and safer work environment, promoting a harmonious

collaboration between human workers and robotic systems.

- Investment Insights: The analysis suggests a strong case for investing

in cobot welders, especially given the comparative financial benefits

over manual welding and the promising return on investment.

- Technological Advancements: The continual technological advancements

are set to further enhance the capabilities, efficiency, and

user-friendliness of cobot welding systems, solidifying their role in

modern manufacturing.